- Separate airtight nozzle closures, meaning no colorant drying

- Very short pump/canister channels, meaning less colorant sedimentation

- Centralized electronics,

meaning fewer parts that can fail - Piston pump technology,

meaning no re-calibration needed

Next level in Tinting

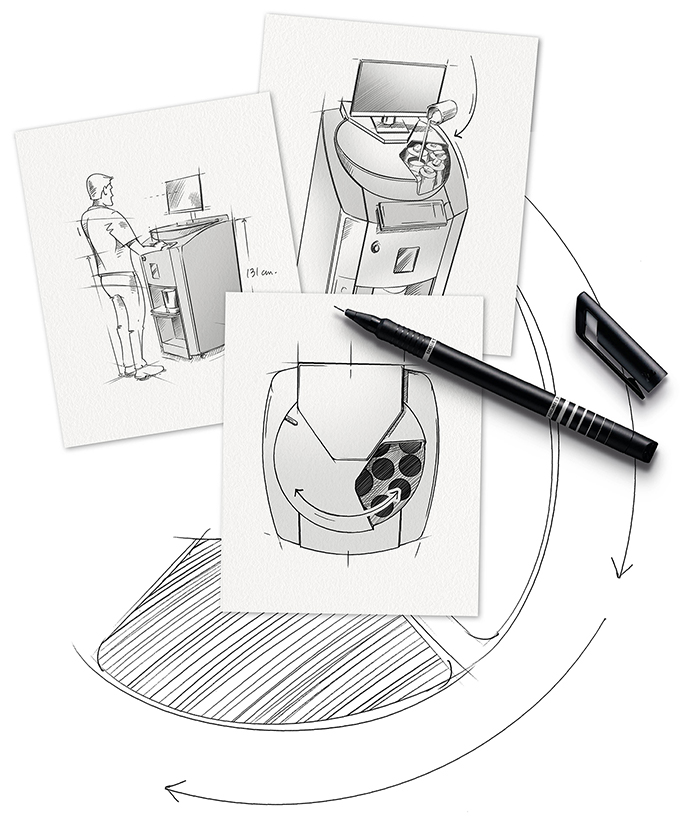

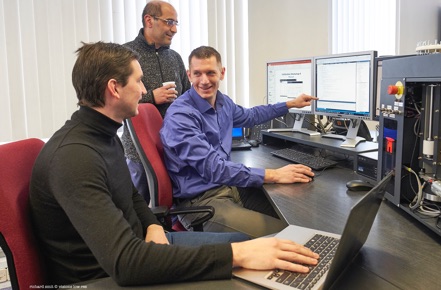

Lifting industry standards is embedded in the Fast & Fluid way of thinking. Relying on over thirty years of market-leading expertise and helped by customer-driven insights, we continue to develop new technologies that make a real difference. For our clients, for their customers.

The Harbil Next Gen Series is a revolution in tinting on every level, based on future-proof technology and user-centered design. Years of market research, product development and testing in the field have enabled us to set a new standard in reliability, dispense speed, operator friendliness, serviceability, and sustainability.

"Involving our customers is an essential part of the development process."

Next level in Reliability

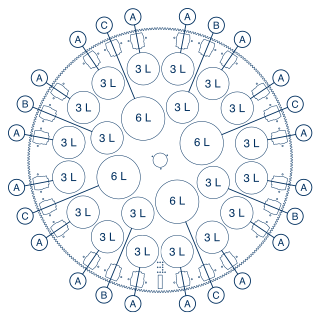

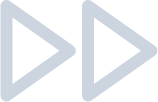

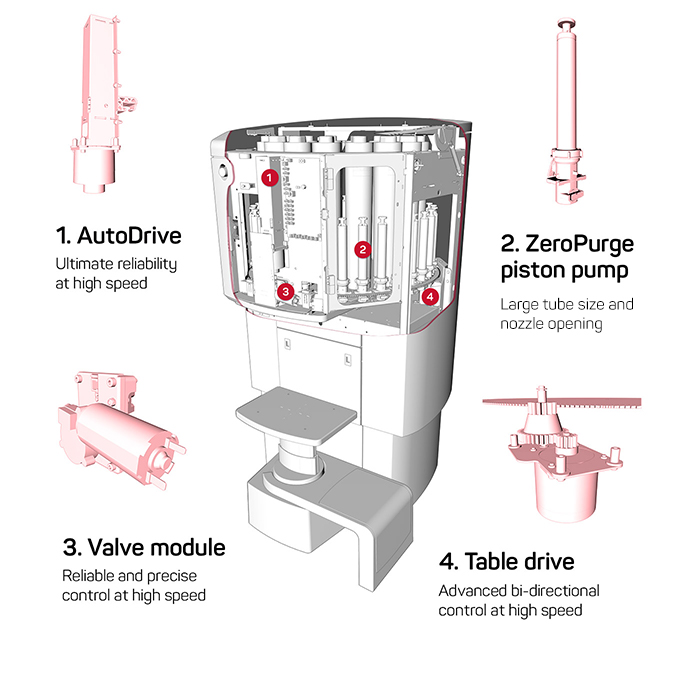

All Harbil Next Gen Dispensers are built upon the success of the proven Harbil® piston pump technology and clean-cut turntable design. Add to this the patented ZeroPurge piston pump, which was launched in 2017, and the Autodrive, and reliable tinting is taken to a whole new level.

What has made the Harbil turntable technology so reliable over the years?

Dispenser reliability has been further improved with the ZeroPurge piston pump. By autonomously flushing the complete pump/canister channel, it takes away the risk of colorant sedimentation and minimizes downtime.

“The Harbil ZeroPurge piston pump is vital to the reliability of the Harbil Next Gen series. To ensure maximum performance, all parts are machined, assembled and tested in-house."

Next level in Operator Friendliness

Harbil dispensers are renowned for their easy-access canister refilling and excellent can handling. By going into the field and asking the right questions, the Next Generation Harbil dispensers are even more operator friendly.

The Operator Display empowers the operator to keep the dispenser in top condition. In fact, first field results show that it makes operators more proactive towards canister refilling.

Next level in Dispense Speed

Until now, reliability always came at a price: a lower dispense speed. With patented technologies like the ZeroPurge pump and the Autodrive in every Harbil Next Gen Dispenser, we have more than doubled the flow rates – ranging from 0.5 up to 2.0 liters a minute*. At the same time, the smallest dispenser has been brought down to 0.05 ml. All while ensuring ultimate tinting accuracy and reliability.

*Depending on dispenser type and pump capacity. See specifications of the HA180, HA480 and HA680 dispenser.

“To increase the dispense speed we had to look at each moving part separately and further optimize the frame stiffness. This has resulted in the development of the fastest turntable dispenser ever built.”

Next level in Serviceability

The Harbil turntable dispenser is renowned for its low Total Cost of Ownership and easy maintenance. But we believe there is always room for improvement. In developing the Harbil Next Gen Series, we focused on increasing efficiency and reducing the TCO even further.

All components critical to the dispenser's operation have been designed as modules, allowing easy replacement within minutes.What’s more, the Harbil Spare Parts system ensures parts are readily available and limits stock complexity.

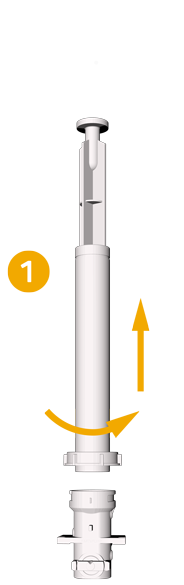

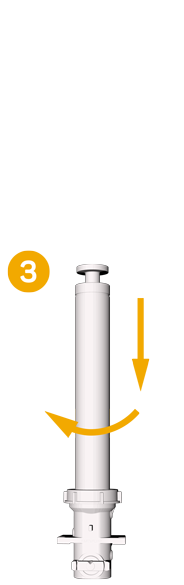

We know that some colorants can be quite tough and may even require a pump/canister exchange. The new set-up enables you to change a complete channel from the front literally in under a minute.

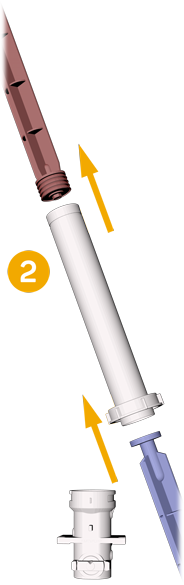

The piston seal can be considered as the only true wear part in the Harbil Next Gen. Changing the seal on the new ZeroPurge™ piston pump is done in just 3 basic steps.

“We developed an entirely new software platform to support all the new features of the Harbil Next Gen Series and to be future proof. One highlight is the Service Dashboard, which takes serviceability to the next level.”

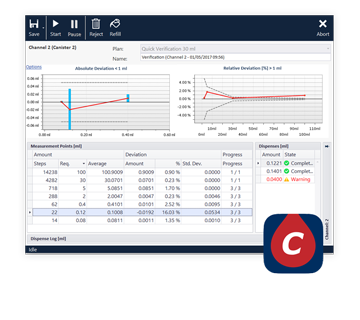

Calibration Workshop

Optimum accuracy and maximum speed is made easy with the Calibration Workshop. And the best thing? You can use the same calibration table for your entire fleet!

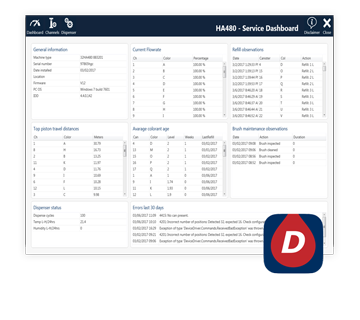

Service Dashboard

All relevant information is stored on the Service Dashboard, giving the service engineer an overview of the dispenser, colorant and housekeeping status at a glance.

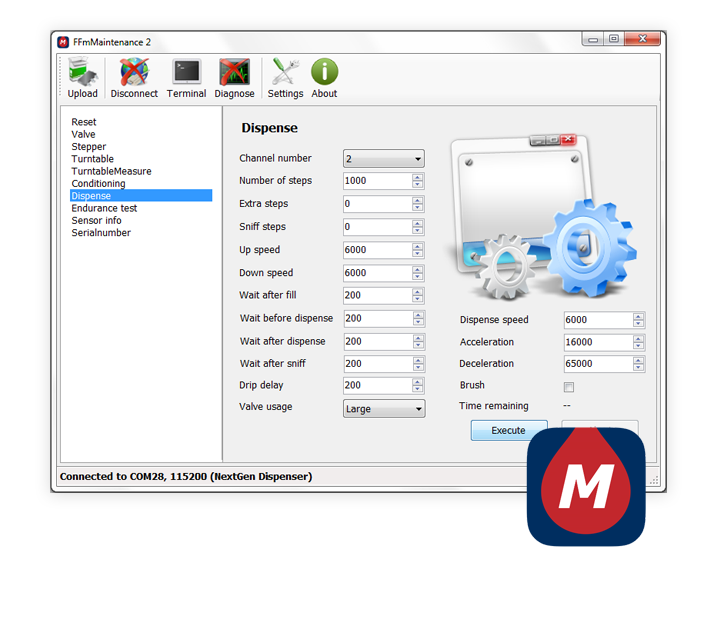

FFM Maintenance

Need to make sure all sensors are OK? The FFmMaintenance tool allows you to check all vital sensors and actuators before physically replacing any components.

Why change parts too soon? Or too late? The Service Dashboard tells you exactly when parts, e.g. the piston seals, need replacing based on their travel distance.

Next level in Sustainability

Being the market leader in the tinting industry comes with certain responsibilities, the environmental impact being one of them. Apart from eliminating purge waste, we have also managed to create the most energy-efficient paint dispenser in its class.

"Tougher regulations mean that colorants are more challenging to handle. All Harbil Series dispensers are built to be colorant proof for today and tomorrow."

No purging

The ZeroPurge piston pump makes life easier for the operator and, by eliminating the purge waste, ensures the Harbil Next Gen is more environmentally friendly.

Mistint reduction

The AutoDrive not only offers ultimate reliability at high speed, it also prevents colorant-related mistints. The result? Significantly less paint waste and a smaller ecological footprint.

Energy efficient

We have managed to reduce the standby power consumption by more than 90% to just 1.8 watts, making the Harbil Next Gen the most energy-efficient automatic dispenser on the market.